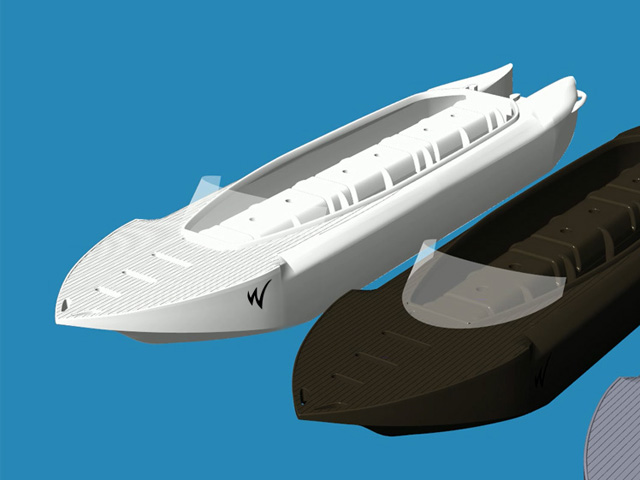

This morning our mold makers sent us these photos of the top part of the cast aluminum rotational mold for the Wavewalk® Series 4 (S4).

Next part they’ll cast in aluminum is the bottom of the mold.

After that, the two parts will be polished and finished, and mounted in a steel frame that will enable attaching the mold to the rotational molding machine.

The last step before the mold is ready for boat production is coating its inside with Teflon.

The first image (front view) shows a slight difference in the parting line between the top and the bottom of the mold, compared to our initial design. This change will enable our rotational molders to place the W logo higher than we’ve shown in the preliminary images and video that we produced. We’re happy about this opportunity to make our logo more visible.

Overall, we’re on schedule for starting production in April.