The Wavewalk® Series 4 incorporates a number of design innovations, including the way its bow is bridged by a structure that can serve as a stand up casting platform.

The S4 bow structure features a pair of molded-in carry handles in its front tip, and four molded-in vertical walls that support the platform on which the angler stands.

This video offers an external view of this bow structure from the top, as well as from below:

But what would we see if we looked inside the bow? –

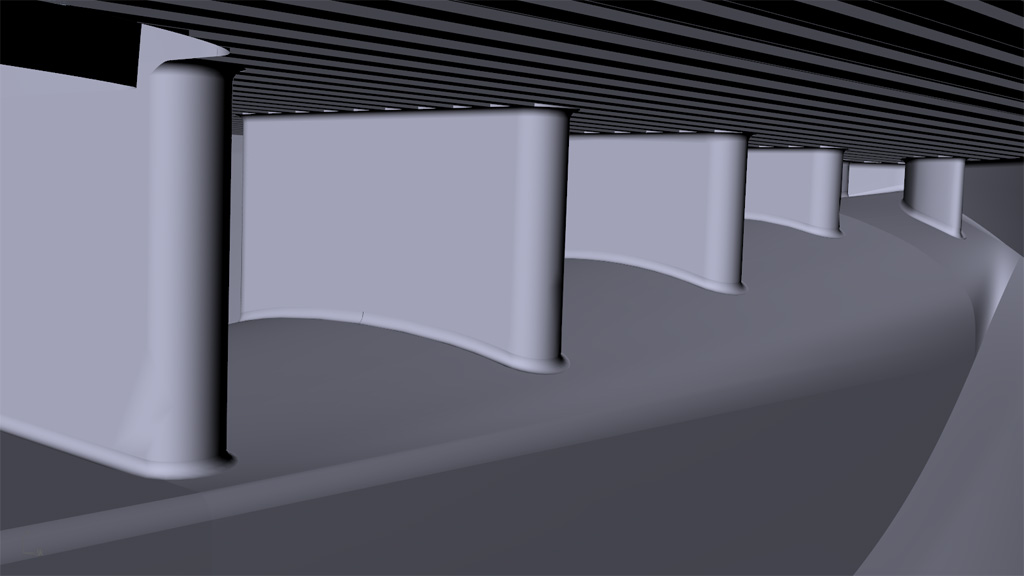

The following image shows the space that’s inside the bow, between the top ‘ceiling’ and the bottom ‘floor’ – The angle of view is that of a person who’s inside the cockpit, and sticks their head in the entrance to the right hull at the bow –

At the right end of the image, we can perceive the inside of the tip of the bow, with one of the molded-in carry handles.

From there and looking to the left, we can see the four vertical walls that support the top of the stand-up casting platform. When standing next to the boat and looking over the bow, these walls’ top parts look like elongated pits (as seen in the video).

The vertical wall that’s the closest to the cockpit’s front end serves as support to a wooden (MDO) wall that’s not seen here. This wooden wall is the top part of a structural element whose lower part is a front saddle bracket. The wooden wall’s top end is inserted into the coaming (spray deflector), and it is attached to the molded-in wall by means of extra-long aluminum rivets. Thus, the wooden wall adds its own support to the stand-up casting platform.

The top surface of the bow’s standing platform features grooves, and the above image shows these grooves as they would look to someone who was in the front end of the cockpit and peeked inside the right hull at the bow.

Readers who are familiar with the W700 saddle’s round ‘holes’, which are molded-in support columns for the saddle’s top, will recognize this function in the elongated ‘walls’ at the bow of the S4.

Yoav,

First, Happy New Year to you and your family.

Second,

I really like how the S4 is project is moving along. 🙂

When will you have the first one ready for your test ride?

I can’t wait to see a video of the S4 in action.

Tight lines and MoPaddle Safe all.

Rox

Thanks Rox,

Happy New Year to you and everyone you care about!

The tooling (cast aluminum rotational mold) for the S4 is projected to be ready for production by the end of March. Realistically speaking, based on our experience with previous projects, we’re talking early April.

Hey, and let’s not forget the weather! After all, we’re in New England, and this usually doesn’t mean good things 😮

Yoav

LOL, That’s true we are in New England, don’t like the weather…wait a minute. 🙂

I guess you would need some open water to do your testing, I wasn’t even

thinking of that. 🙂

Down towards the shore in Ct most our fresh water lakes are open, but go north and

we’ve got ice.

Well lets all pray for an early spring, we got some yakking to do. 🙂

Tight Lines and MoPaddle Safe all.

Rox

Larry already ordered a demo S4 unit, so we’ll have videos to show even if New England is snowed over, and the lakes here are all covered with thick ice 😀