This article offers suggestions for making a wheel cart for your kayak, portable boat, kayak-skiff and cartop microskiff from the W700 and S4 series.

Sadly, we haven’t found a commercially available canoe or kayak cart that we like.

There is no perfect wheel cart for a portable boat, or a cartop microskiff, because the requirements from such a device can vary greatly, depending on the weight of the boat (motorized or non-motorized), the terrain on which it needs to be carried, and whether there is a need to transport the wheel cart on board the vessel.

General guidelines

These recommendations are valid for all types and sizes of wheel cart, regardless of boat model, and of the weight it carries. Whether you need to carry an empty W720 that weighs just 80 lbs, or a 100 lbs S4 outfitted with a 60 lbs 6 HP outboard motor, which brings the total weight of the boat to 160 lbs even before you load it with your fishing gear, you want your wheel cart to be sturdy and stable, and make it as easy as possible for you to go on whatever terrain you need to travel on.

Simple is Best

The wheel cart design we recommend is robust as well as easy to make, even if you’re not an expert carpenter. It’s also inexpensive and durable. This design consists of a 2×4 or 2×6 lumber, a steel axle, a pair of wheels, and two latches. The axle is attached directly to the underside of the lumber “body” on which the boat rests. The wheels are mounted on both sides. The boat is attached to the wheel cart body by means of two latches.

Dimensions

- Length of the lumber body: 35″ for the W720, and 42″ for the S4. This means a 2″ clearance on each side.

- Lumber size: 2×4 for a non-motorized W720 and S4. 2×6 for a motorized W720, and S4. This means you upgrade from 2×4 to 2×6 if the total weight of the boat plus its motor is equal to or exceeds 100 lbs.

- Waterproofing: Wood rots and steel rusts, so we recommend coating all parts of the wheel cart with 2 coats of urethane.

- Wheel diameter: Minimum 12″, even for flat and even terrain. This requirement has to do with the size of the boat, and the clearance from the ground. For very rugged terrain, such as trails in the woods, don’t hesitate to use 20″ diameter wheels.

- Wheel width: Minimum 2″, even for flat and even terrain, and pavement. Minimum 6″ for sand.

- Type of tires: Flat free. The last thing you want when you’re out there is a flat tire, and not having a spare tire…

- Wheel material: Plastic is lighter than steel, and it doesn’t rust.

- Steel axle: Minimum diameter 5/8 for lite duty wheel cart, and minimum 3/4 for heavy duty one. Stainless lasts forever but it’s more expensive. Remember to make the axle long enough!

- Attaching the axle under the wooden body: Anything goes, from plumbing brackets to simple nails bent with a hammer, pieces of wood, etc. Build strong!

- Attachment points for the latches: You can drill a pair of narrow holes on each side of the lumber body, or outfit it with O screws fore and aft. Preferably, keep the biggest distance between the two attachment points, in order to minimize torsional movement when you’re pulling the boat.

- Latches: Preferably wider than 1″. Ratcheting latches are overkill.

- Where to attach the wheel cart to the boat: The optimal spot for the wheel cart is right below the boat’s vertical mounting plate, because this location provides means to secure the latches more effectively, and prevent slipping. If this spot is not convenient (e.g. due to weight distribution), any spot between the middle of the boat and the rear end of the cockpit is fine.

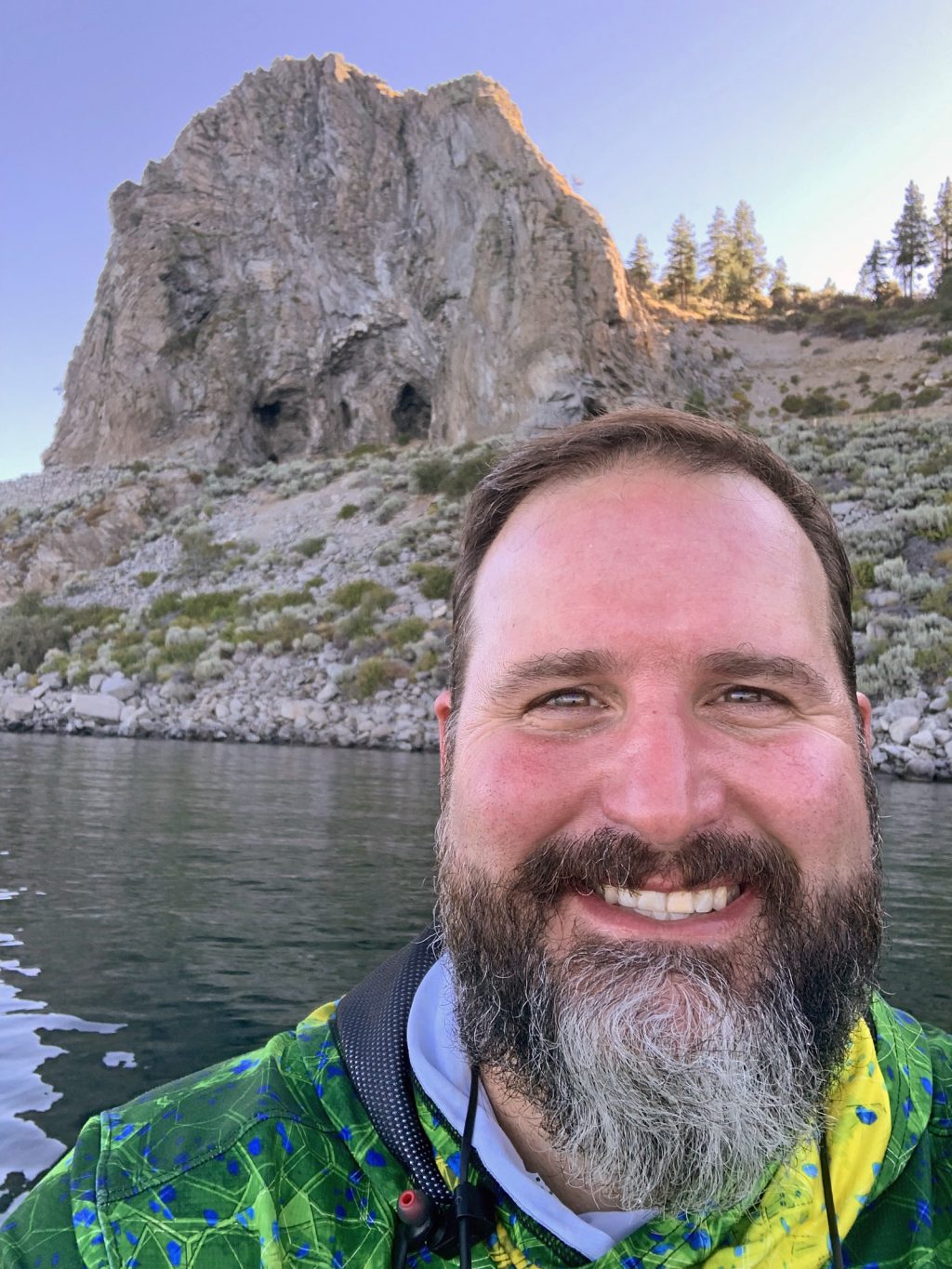

- Carrying the wheel cart on board: The two pictures in this article show the preferred way to do it. For the S4, adding a transversal piece of wood in the middle of the cart can help keeping it in place if rough waters, by inserting this element into one of the vertical slots in the boat’s front deck.

No wheels, sled style

If your W720 or S4 are non-motorized, and you don’t carry heavy gear on board, and the surface on which you’re carrying the boat isn’t abrasive (e.g. grass, sand, pebbles), consider dragging the boat sled-style, with no wheels. It can make things simpler and easier, and it won’t necessarily damage the boat.

Central beam, if you can leave the wheel cart on shore

A central beam is attached to the middle of the wheel cart, and it stretches forward along the center line of the boat. The front tip of the beam is attached to the tip of the boat’s bow (S4) or bows (W720).

Pulling a boat that’s attached to such enhanced wheel cart is easier, because the beam helps keep the wheels going straight forward, and not sideways, as they might tend to do if they’re not attached properly. This full fledged cart is too big to take on board your vessel, so this solution works only for users who can leave their cart on shore after they’ve reached the water.

Do you have any questions for us?