By Captain Larry Jarboe

Yesterday, the sun came out and the wind died down enough to try the 2 cycle 2.5 Mercury short shaft outboard (an old rebranded Tohatsu) that I picked up for a hundred bucks. It now has a new carb and an aluminum prop. Essentially, with some minor changes, it is souped up to become the 3.3 hp Merc motor that is still marketed around the world where 2 cycle outboards are not discriminated against.

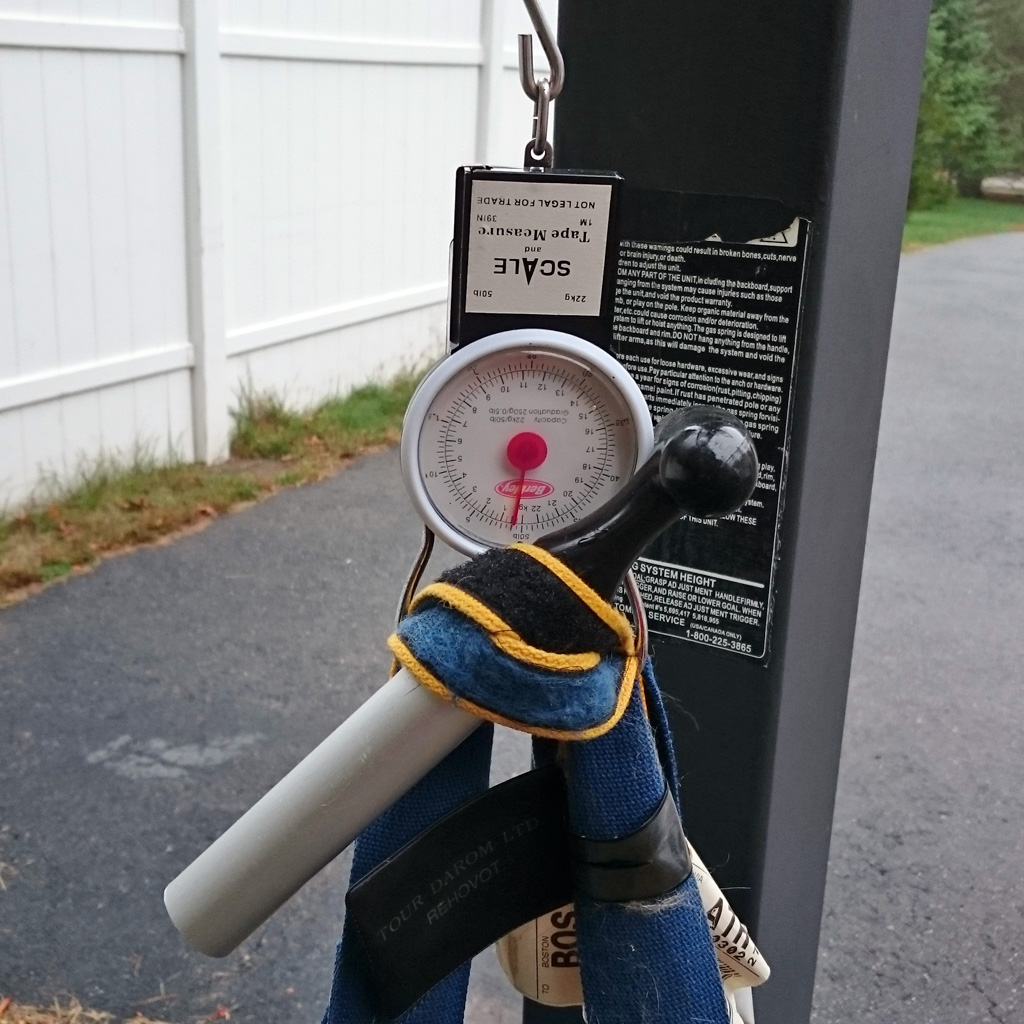

Notice, I mounted it on my vessel using the smartly designed W700 transom bracket that allows for long or short shaft outboards. Also, I put a concrete block in the bow to help balance the load.

Turning the bracket upside down for the short shaft also means the motor is another 6 inches aft. This is necessary to tighten the motor clamp bolts which are down between the two hulls.

That extra distance aft requires a level of dexterity to reach. After some personally challenging contortions to face astern, I started the motor. Then there were equally challenging physical maneuvers to spin around while underway. That nice lightweight motor (28 lbs.) has no neutral, only forward.

The motor does turn up sufficient torque to make the boat plane smoothly. But, the lowered transom digs into the water during the transition thus throwing water into the face of the engine. That is not good, at all.

Putt putting around was fine. Planing the W700 with the short shaft motor is presently unacceptable. Maybe, a joystick option or more weight in the bow might alleviate the lowered transom grabbing water. Or, a spray shield installed in front of and under the transom bracket. I, personally, want a daily driver with minimal maintenance issues. And, easier reach to start and service the motor.

Yoav, has consistently been recommending the log shaft outboards. I thoroughly concur. The short shaft Mercury would make a good display engine for sales but it runs so well I am putting it up for sale and looking for a 3 hp long shaft as the most ideal power source for my application.

Also, Yoav’s recommendation for Tohatsu small outboards is right on. The Tohatsu engines are probably the most affordable and dependable small outboards on the marine market, today. Mercury, Nissan, and Mariner use the Tohatsu power head and drive that they rebrand with their own logos. If you remember to 1) always use non-ethanol fuel and 2) after each use, flush with freshwater, while 3) running the carburetor dry, and 4) store upright, your engine will last a lifetime.

However, until my short shaft outboard sells, a transom well will not be too difficult to construct. And, some yoga exercises prior to getting underway might not be too terrible. Easier than a Zumba class…

Larry J.

Read much more and see pictures and video in the comments below ⇓

Read much more and see pictures and video in the comments below ⇓

More fishing adventures and outfitting tips with Capn’ Larry »