By Gary Rankel

Nature Coast Kayak Fishers Club

A few years ago, not knowing any better, I submitted a short piece showing how to install an anchor trolley on my Wavewalk 500.

Having had 10 years experience and hundreds of fishing trips in my Wavewalk fishing machines, I’ve come up with a number of ideas to simplify rigging the W for fishing, one of which makes the anchor trolley idea obsolete.

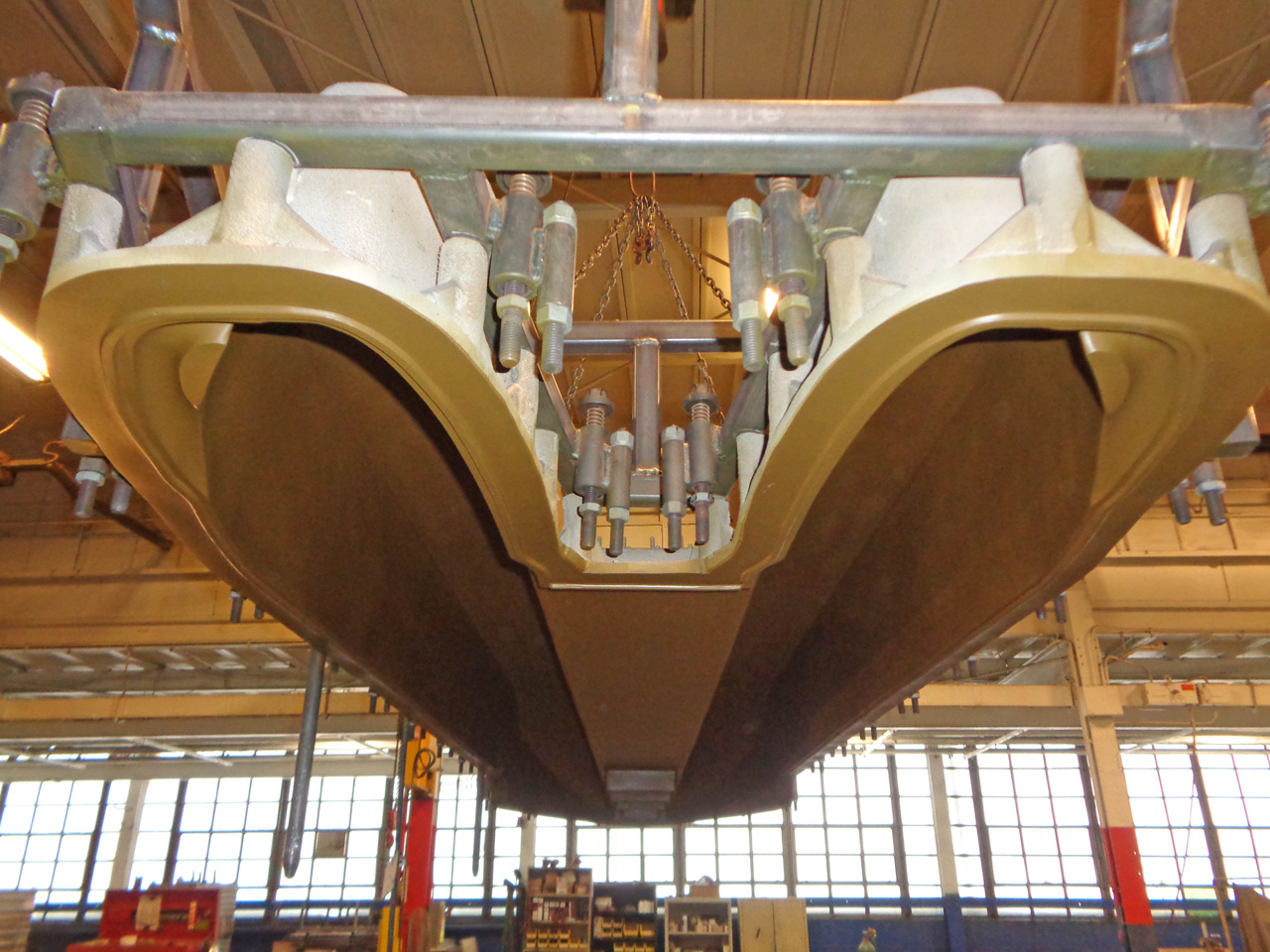

While anchor trolleys are useful additions on mono hull yaks, the twin hull design of the W offers a much easier alternative.

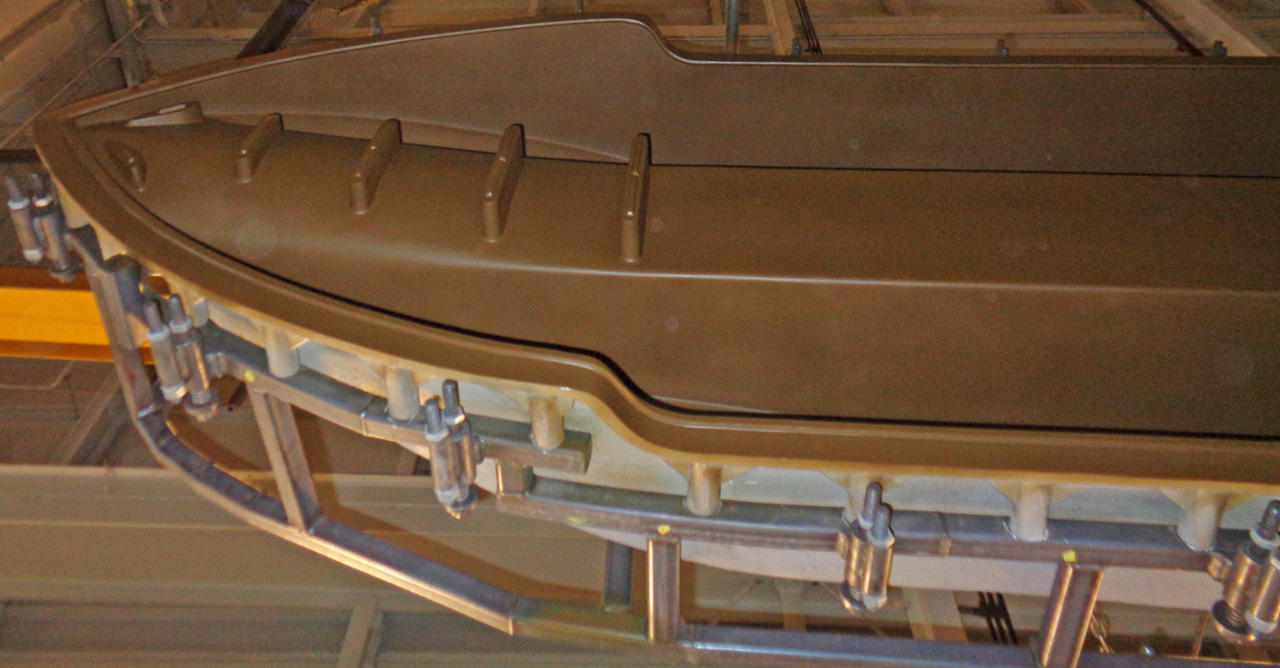

All that is required are 2 holes drilled into the fore and aft cockpit rims (ignore the third middle hole in the photo used for another purpose), through which cords, knotted on each end, are attached.

Simply attach a plastic snap clip onto both the cord and anchor rope and “anchors away”. Deploy the anchor to the front or rear depending on which way the current is flowing. This is about as simple as it gets, with no banging of hardware on the W to spook fish.

This arrangement works with the W700 as well, however, the deck mount will prevent it from working on the front of the new S4.

Hope this helps Wavewalk users looking for a simple anchoring fix.

Read more about Gary’s kayak fishing trips »

Read Gary’s review of his Wavewalk 500 fishing kayak »